Reconditioning of CNC Machines

Reconditioning of CNC Machines

Reconditioning of machine tools involves a comprehensive process that restores equipment to optimal performance levels. Skilled technicians meticulously inspect the machine and its sub-systems, identifying wear and tear that impacts functionality. We replace worn components, recalibrate systems and replace old electrical systems with latest CNC controllers as per customers preference. By installing advanced technologies, reconditioning enhances operational efficiency and reduces downtime. This activity not only extends the lifespan of the machines but significantly cuts maintenance costs. Moreover, reconditioned machines often consume less energy, aligning companies’ goals to sustainability.

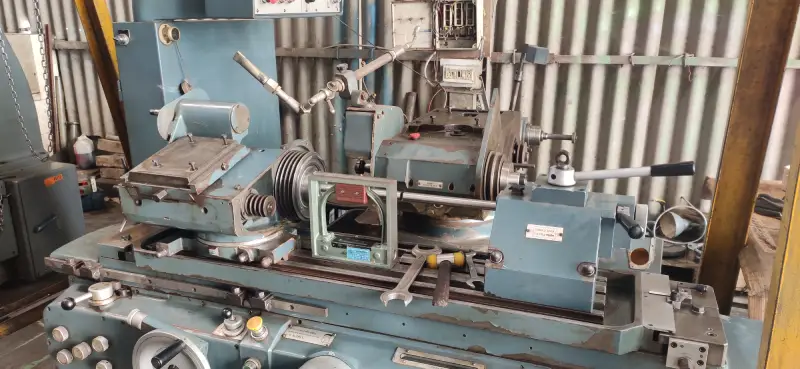

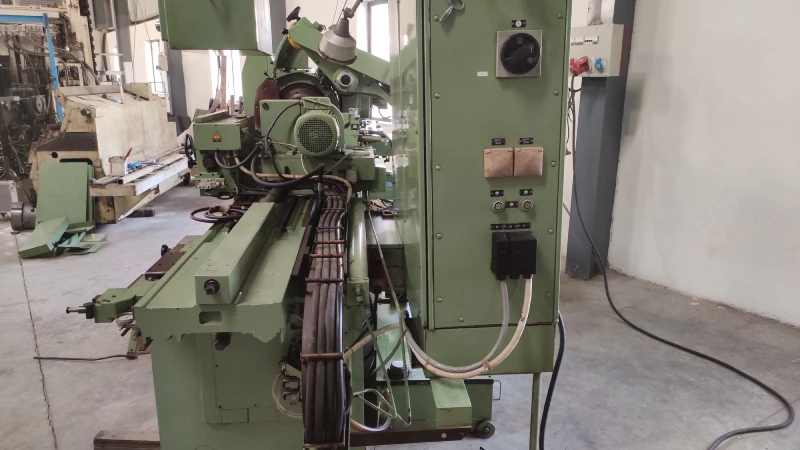

Jones and Shipman Universal Grinding Machine.

Reconditioning of Universal Grinding machine with new electric circuit / wiring.

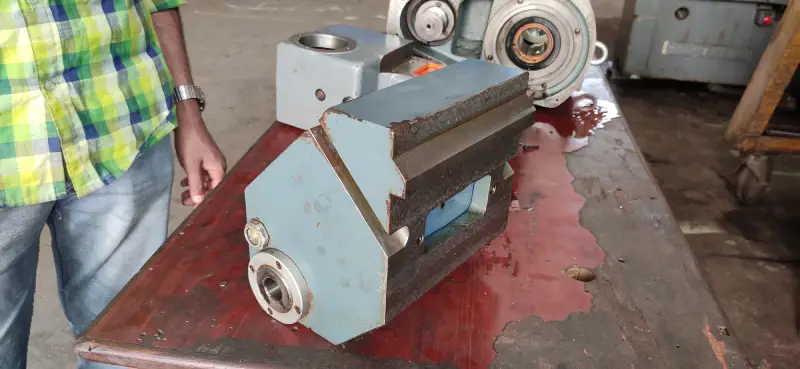

Simultaneous Boring SPM.

Design and manufacturing of simultaneous boring machine.

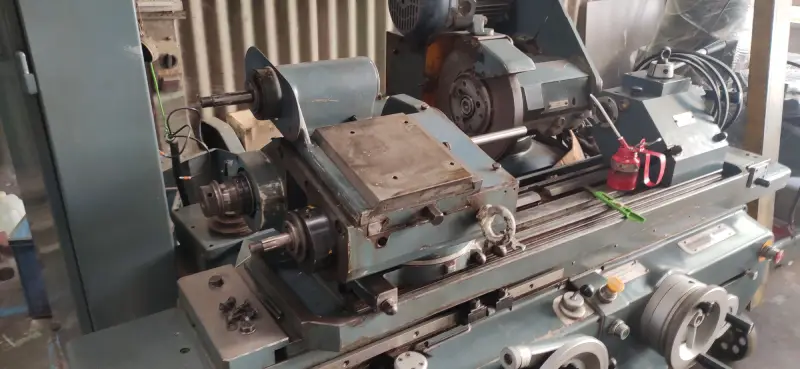

Jyoti VMC 1050

Reconditioning and Retrofitting of Jyoti VMC 1050. We installed a new Mitsubishi controller (M80) on the machine.

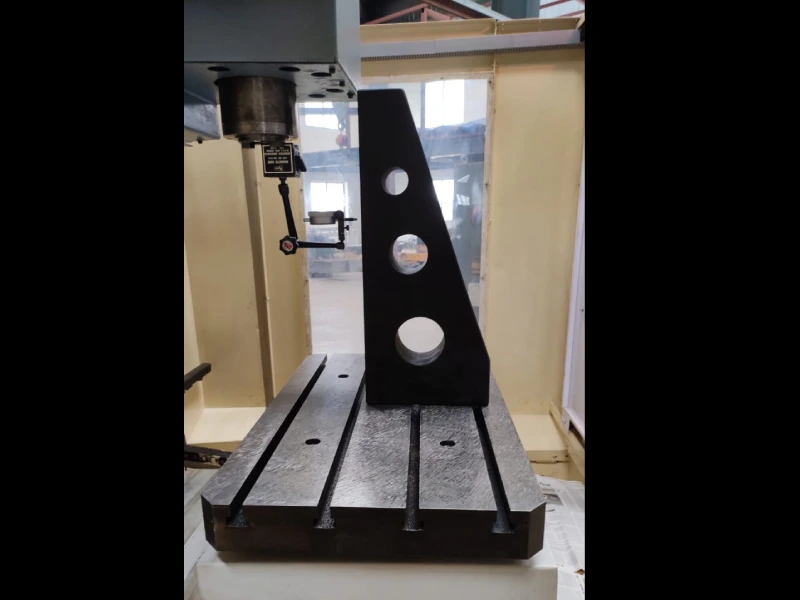

WMW BWF Face & ID grinding machine.

Reconditioning and restoring original accuracy as per company accuracy charts.